1. Definition:

Fluorescent penetrant inspection refers to a method in which a penetrant containing fluorescent substances is coated on the surface of the inspected part, penetrates into the surface defects through capillary action, and then cleans the penetrant on the surface, and retains the penetrant in the defect for imaging. Among them, fluorescent penetrant detection is widely used in aerospace and military weapons.

2. Classification and analysis:

Ø Sprinkler irrigation:

Advantages: using colored penetrant flaw detectors, cleaning agents and developers or fluorescent penetrants, cleaning agents and developers, low cost of use, small footprint, slow efficiency, and sealed consumables without contamination

Disadvantages: But it is only used for small workpieces or local workpieces, and the efficiency is slow.

Trough type: It is divided into two design modes: automatic and semi-automatic. Lifeng can carry out non-standard design according to the user's plant layout and automation requirements. The post-emulsion fluorescent penetrant detection can adopt the groove type, which can control the detection process more accurately.

Advantages: It is suitable for the inspection of aviation parts of various shapes and sizes of workpieces, and it is also suitable for the inspection of aviation parts in small batches.

Disadvantages: For complex structural parts such as holes, it is difficult to cover the permeate and emulsified liquid. For large workpieces, the workpiece needs to be turned over, the penetration time and emulsification time are not easy to control, and a lot of fluorescent wastewater is generated, so fluorescent wastewater treatment equipment needs to be purchased.

Ø Electrostatic spraying: divided into automatic electrostatic spraying penetration line and manual electrostatic spraying penetration line. Electrostatic spraying penetration flaw detection line, the workpiece is conveyed and moved at each station by means of a hanging chain. Each station is controlled by PLC, and all station data can be monitored on the HM man-machine interface control system. The manual electrostatic spraying penetration line can automatically realize that part of the process is controlled by PLC, and the workpiece can be transferred by electric hoist or roller elevator or manually at each process station.

Advantages: Applicable to parts of various shapes, can reduce the use cost of permeation consumables (compared to trough permeation lines), and can perform assembly line operations.

Disadvantages: high purchase cost, large floor space, and a lot of fluorescent wastewater, which requires the purchase of fluorescent wastewater treatment equipment.

3. Post-emulsification penetrant inspection process and scope of application:

Dry powder imaging method: pre-cleaning, infiltration, dripping, pre-washing, emulsification, dripping, final washing, drying, dry powder imaging, inspection, and removal of the developer.

Water-based wet development: pre-cleaning, infiltration, dripping, pre-washing, emulsification, dripping, final washing, water-based wet development, drying, inspection, and removal of development.

Non-aqueous-based wet development: pre-cleaning - infiltration - dripping - pre-washing - emulsification - final washing - drying - non-aqueous-based wet development - inspection - developer removal"

The post-emulsion penetrant inspection method is suitable for the following situations: (1) inspecting large-volume parts; (2) inspecting parts that require higher sensitivity than water-washing penetrant inspection methods; (3) parts contaminated with acid or other chemical agents , and these inspections will be harmful to the water-washable penetrant flaw detector; (4) Inspection of shallow and wide openings for defects; (5) Inspection of parts that may be contaminated by dirt during use; (6) Inspection of stress and Grain boundary corrosion crack defects (use the most sensitive penetrant); (7) Inspection for grinding crack defects; (8) Sensitivity must be variable and controllable so that while harmful defects are detected, non-harmful defects can be let go.

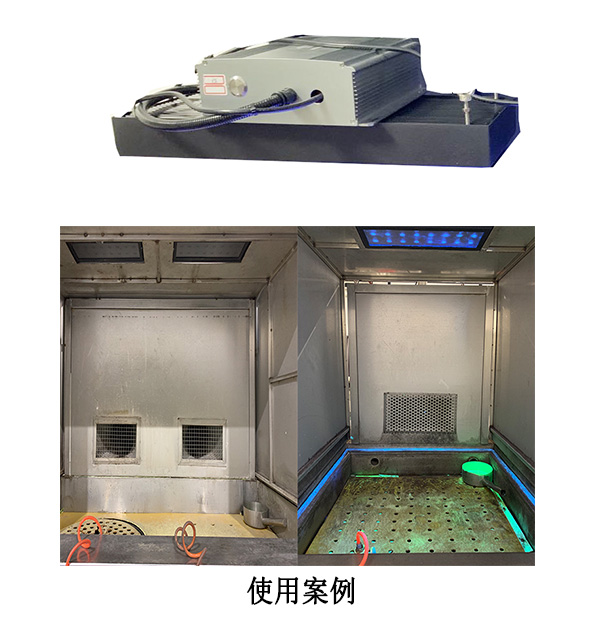

The cleaning of the post-emulsification requires a removable darkroom and a black light for easy cleaning. To this end, Lifeng has specially developed LED black light lamps suitable for cleaning stations, which replace the traditional UV-400 lamps.

4. What factors should be considered when choosing a penetration line?

Penetration inspection lines are all non-standard customized, so the main factors to consider before designing the plan are: the shape of the penetration workpiece, material, whether heat treatment is performed, the size of the workpiece, plant layout, penetration testing method, penetration sensitivity and execution. standard.

5. Auxiliary equipment:

5.1. Auxiliary equipment of trough penetrant inspection line includes ultrasonic cleaning machine (cleaning test block), material frame, cart, white light meter, black light radiation meter, fluorescent light meter, refractometer, black light lamp, auxiliary lighting lamp, magnifying glass and penetration five-point test blocks, etc.

5.2. The electrostatic spraying test line includes white light meter, black light radiometer, black light, auxiliary lighting and penetration five-point test block, etc.