1. Immerse the workpiece in a beaker filled with 3500P fluorescent penetrant, take it out immediately, and leave it for 10 minutes. Since there will be sagging during the placement process, use a dropper to add penetrant on the way.

2. Rinse the workpiece with tap water for about 20 seconds to remove excess penetrant from the surface.

3. Use 3500R special emulsifier (1:4 dilution), drop the dropper on the surface of the workpiece, observe the emulsification state under a black light, rinse it off with tap water after 1 minute after the emulsification is complete (there is no fluorescent background on the surface under the black light, emulsification agent residue), shake off the surface water droplets.

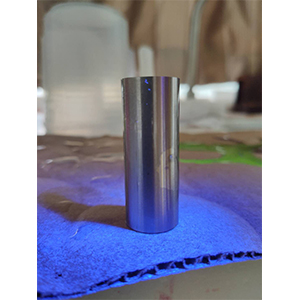

Drop emulsifier

Washed

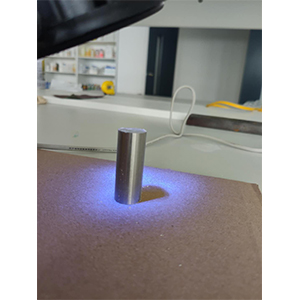

4. Dry the residual water on the surface, use a small brush to apply a dry powder developer on the surface, observe it under a black light after 10 minutes, and the result shows no natural defects.

Drying

Apply developer powder