How to prevent the occurrence of spark burns in the magnetic particle flaw detector in the two magnetization methods of the electrification method and the contact method

1. The reasons for the ignition and burns caused by the electrification method are:

① There is rust, oxide scale and dirt in the contact part between the workpiece and the two magnetized chucks;

② The magnetizing current is too large;

③ Insufficient clamping pressure;

④ Clamp or loosen the workpiece while the magnetized chuck is energized.

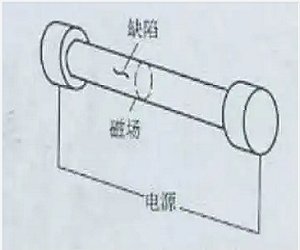

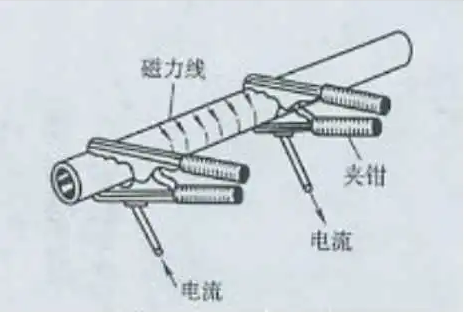

Figure 1 Electricity method Figure 2 The clamp is powered on

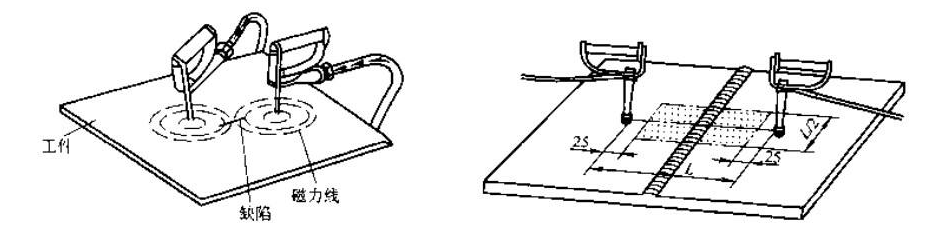

2. The reason for the spark burn caused by the contact method is: mainly due to poor contact

Figure 3 Contact method

3. The measures to prevent fire burns are:

① Remove the rust, paint and non-conductive coating from the contact part with the electrode;

② It is harmful to cover the magnetized chuck with lead pads or copper braided pads with uniform thickness, and lead vapor should be ventilated during use. Copper braids are only suitable for metallurgically permitted occasions;

③ The magnetizing current should be turned on when the clamping pressure is sufficient;

④ The workpiece must be clamped or released when the magnetizing current is cut off; magnetized with a suitable magnetizing current.

Figure 4 Copper woven mat