1. Structural characteristics

1.1. The material of this machine is strictly selected, scientific and reasonable, and adopts Japan's Mitsubishi PLC program controller, which has strong anti-interference ability. Improve the degree of automation, durable, stable performance, safe and reliable.

1.2. This machine adopts high-performance digital phase-shift trigger circuit board, which makes the thyristor trigger more reliable. Never break down the thyristor.

1.3. Integrate many functions of the flaw detector into one, and use various function keys to control the operation.

1.4. In addition to magnetizing and demagnetizing functions, it adopts current tracking design, and the output current is accurate.

1.5. Over-current and under-current alarm output, no missing detection.

1.6. Power-off phase control, stable remanence.

1.7. Computer monitoring and observation, crack image collection, flaw detection report recording, storage and printing, and communication interface with various types of computers.

1.8. The closed coil will never burn the workpiece and injure the operator.

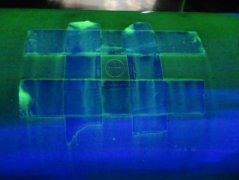

1.9. Using closed coil induction method and direct energization method, the entire wheelset is magnetized once, and all cracks in the wheelset, such as the rim, tread, wheel complex, wheel axle, wheel center, gear, tooth root, and the gap between the wheel and the gear, are completely removed. All-round display is available.

2. Flaw detection process:

Wheelset feeding---conveying track---wheelset enters magnetization position, left and right electrodes clamped---left and right coils enter, opening and closing coils descend and close-spray, magnetization-coils loosen and rise-- The left and right electrodes are loosened, and the coil is withdrawn--the wheel set is transported to the observation station--automatic camera, the wheel set is moved and automatically filmed, saved--transferred to the cleaning station for high-pressure spray washing--hot air drying--unloading